schick 14 - record player

schick 14 - Plattenspielerschick 14 – the record player

With the record player it is the same story as with the tonearm: historical models are appealing, but rare and often a full restoration has to be done first to reach a top notch sound. Even then historical compromises are still inherent.

Well – time does not stand still. That is of course true for record player components. Especially modern motors can deliver stunning results. Still, the recipe to make a record player today seems mostly very, very simple: cheapest weak motors, thin unstable bearings, belts with yoyo effect, heavy platters, heaps of flashy materials which result all in all in a very dull and lifeless sound.

The schick 14 takes over where the great analogue era may have ended: with the latest record cutting lathes. The platter has, like these cutting lathes, a diameter of 14 inches, hence the name schick 14. This platter size still allows the mounting of 9 inch tonearms. The weight of the platter is ‘only’ 4,5kg. But why this large diameter and a comparatively low weight? The flywheel momentum of that dimension is much more than a heavy 12 inch platter can reach. So heavy platters do not solve problems, but actually create new ones for the bearing and motor. With a larger platter the momentum is high, but bearing wear and pressure are very small. Regulation of the motor is not translated to the platter as well.

The platter is cast from an aluminium-magnesium alloy, just as the best historic predecessors. Casting (without pressure) results in lowest tensions of the material with a highly desirable resonance pattern. Today this process is optimized so there are almost no cavities in the cast. This process is not to be confused with die cast method for large quantity parts.

In combination with a very strong motor a drive with highest precision is realized.

Motor

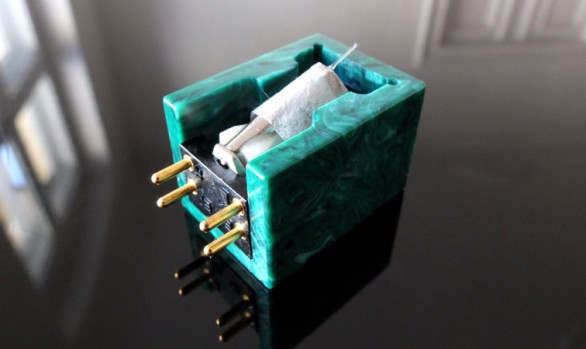

I have been looking for a suitable motor a long time and found a suitable one from a German manufacturer. Normally small and weak motors are chosen. This really top level motor I, have chosen, is used in medical and critical industry applications. It is a brushless DC motor, which has very high torque and is yet absolutlely quiet. It is finely balanced and has a high mass rotor. The bearings run in low noise material cages. This way an extremly stable and quiet drive find its place in the schick 14 record player.

The motor allows programming of all its parameters. This motor is not programmed for maximum power, but for most smooth and constant operation. A feature that was unavailable for the AC motors of the vintage record players. Compared to its vintage brethren this motor is just leaps ahead.

Plinth

The plinth material comes from industrial tooling and has the appearance of a stone or of fine suit fabric. The material is a high-density polymer. This material has almost ideal damping characteristics. It dampens but is not ‘ dead ‘.

High and low frequencies can be absorbed very quickly in the material. Unlike hard materials there will be no vibration energy stored. It’s heavy, but not too heavy. Heavier than wood, but lighter than slate or stone. Heavy material tends to store the vibration energy longer but often these do not absorb it.

Due to the high mass of such a material it will resonate later, resulting in a smeared sound. Materials which absorb only low or high vibrations, result in an unbalanced sound.

The material is also extremely dimensionally stable. It barely moves at temperature differences that exist in living rooms – well practically it does not move at all – unlike wood. These positive characteristics however are reflected in a high material price – it is about seven times more expensive than mahagony! But the CNC processing allows an affordable production.

The machining also allows tailored cutouts for bearing and motor. Clumsy levers and and adjustment bars can be omitted.

The plinth fits the record player like a glove. Thus I achieved greater stability than regular large area cutout plinths from any other material.

Idler wheel

The force of the motor is transferred by an idler wheel of large diameter, which drives the platter horizontally on the inner side. This results in a very high torque drive. Slip and yoyo effects, like with a string or a rubber belt, are eliminated.

Besides delivering a very dynamic sound a well made idler wheel with modern parts, combined with a modern silent motor, can deliver a rumble free platter drive. Modern rubber is much more consistent compared to the unequally hardened idler wheels in old record players.

The idler wheel is mounted on a special ball bearing. A regular, single bearing would ring, but there are special constructions with more than one row of steel balls.

It runs really smooth being designed for 24/7 use with high rpm, so again that will last ‘a while’…

Then there is a set screw for idler wheel pressure.

Some vinatge models had this feature. Very helpful. You can dial a ‘non hand stoppable’ torque or the regular ‘one finger stops it’ feel.

Isolation feet

Every schick 14 record player is delivered with three magnetically damped feet, which have a very good damping in vertical direction but are not able to swing sideways. This avoids the feeling of a wobbly sub-chassis and the negative effect of circular movement of the record player.

By the way, that was exactly the research result when EMT designed the damping feet for their 950 model.

Bearing

Again vintage concepts were chosen when they proved to deliver best results. Bronze bushings and steel ball are perfect examples for that.

But the bearing incorporates some high-tech as well.

The trust plate is made from PEEK. (Polyether ether ketone, not the soft and cheap POM)

PEEK is used for example in high performance engines as chain-guide, where low wear is demanded.

Now, if it stands +100.000 miles in a hot car engine, 33rpm at room temperature are an easy task again.

The lubricant is high-tech, too: a synthetic fluid (oil) which features: ‘Low noise, resistant to oxidation, good viscosity temperature behaviour’ – according to the manufacturer’s data sheet.

The latter means -40°-+140° C… In room temperatures it has constant viscosity. So, even on a cold day the bearing does not stick a bit more than on a hot.

Seems like a modest thing to ask for, but most lubes used in record players do not behave like this .

Conclusion

You see, the components of the schick 14 resemble those of the popular vintage idler wheel record players. Despite its minimal design, there are quite a few features in this record player. Where improvement was possible by modern technology it was carefully applied. This is especially true for the motor and its programmable regulation.

I avoided unnecessary levers, tension springs of the original designs. Small parts count of exceptional quality, just like with my tonearm. Classic concepts are transferred to the modern and let a record player dream become reality, mine and possibly yours.