Apogee Caliper

My Apogee Odyssee

I heard Apogees for the first time on the High End exhibition in Frankfurt 1988. I liked them a lot, but settled for smaller conventional speakers, because as a student at that time I could neither afford them, nor place them somewhere in my room.

Then, in 2002, the time was right and I finally found a pair in a shop in Basel, Switzerland, that were waiting for a restoration.

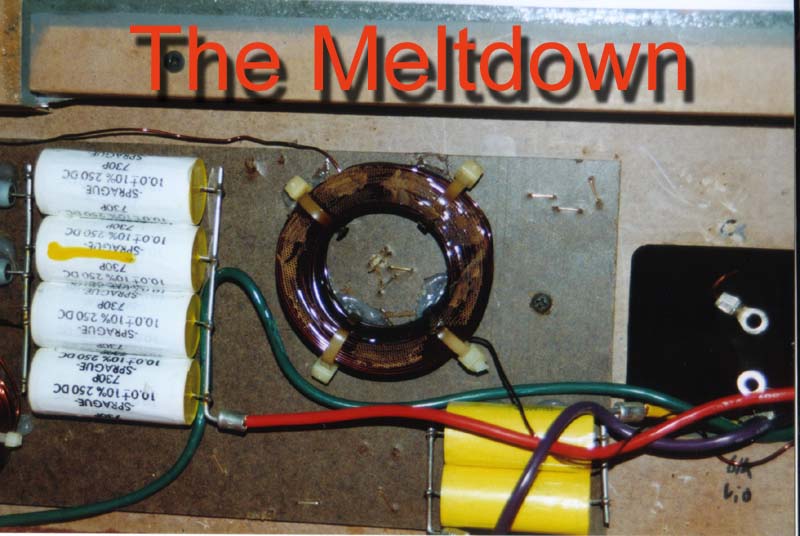

They must have driven very hard, since one of the coils in the frequency network was totally burned. However the tension of the bass panels was still ok. However, I had to straighten one of the mid/treble units.

There were coffee spills on the bass panel, not to speak of the ‘diluted’ foam damping on the edges of the bass ribbon. So there was a lot of work to do.

Let’s start with the frequency network. One coil was destroyed completly, but a critical look at the other components led to my decision to replace every part here. The coils used were just loosely wound. This means that they are prone for mechanical resonance. Indeed they produced a rattling sound when knocking on the cardboard carrying base.

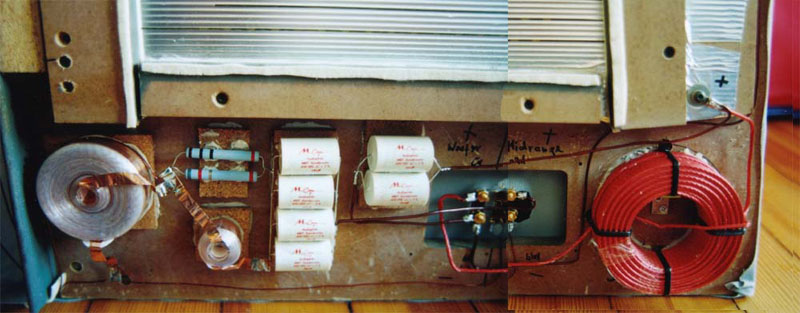

I removed the cheap base entirely. The new elements were were placed seperately on a cork base.

The choice of the bass coil was somewhat limited due to size restrictriction in height possible to hide in a FLAT panel speaker.

I chose an ‘Intertechnik Tritec’ coil for the bass coil. However it was not a compromise since it is the top-quality product. It is tightly wound and then baked togehther. They seem to be one piece rather than wound togehther. The smaller coils for mid treble and all caps were bought from German maufacturer Mundorf ( Mundorf CFC coils and low tolerance M-Caps) , famous for their high quality speaker parts. These coils are made from copper foil and then glued together with some sort of Epoxy. Again these parts are very resistant against mechanical resonance, as they need to be inside the panel.

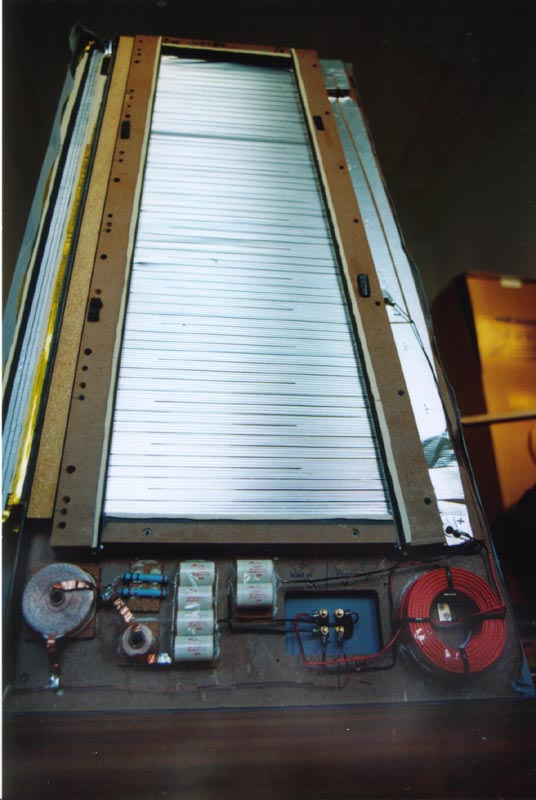

The finished network looks like this. I prefer solid core cable and did the internal wiring with the reamaing unwound wire of the bass coil. From the rest of the coil I braided 2 lines togehther and use it as loudspeaker cable! It sounds much better than any other cable I tried.

I have replaced the foam damping on the inside, as well as on the outside of the basspanels with felt strips of matching size. They do a very good job. I swept sine signal through them with no trace of the feared ‘Buzz’ sound.

Here is a schematic with the original cap brand name:

Another view from a finished panel. For me it was a good decision to get a damaged pair rather than one in good condition. The process of restoring them made me understand how they work much better, also it is a nice feeling to have them finished yourself.